Important Private Lines in Great Britain

RAILWAYS OF BRITAIN - 26

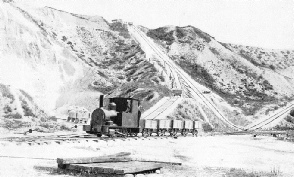

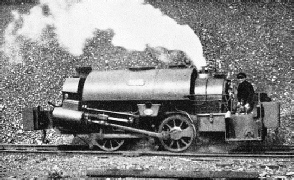

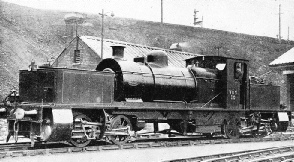

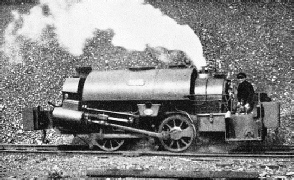

A SMALL TANK LOCOMOTIVE at work on the industrial railway at Beckton Essex, belonging to the Gas Light and Coke Company. The locomotive is specially reduced in height for working over lines with limited head-room. The system includes thirty-four locomotives and more than 1,000 wagons.

SOME of the most remarkable railway lines in Great Britain are little known. No passengers pass over them and, not infrequently, the lines and rolling-stock are so situated that the public sees very little of them, certainly not enough to receive a lasting impression. Yet some of these railways, owned by collieries, ironworks, gas companies, quarry companies, and all kinds of industrial organizations, are of great importance.

We are familiar on the railways with goods wagons bearing the names of private firms, but we seldom wonder whether their proprietors may have a complete private railway system of their own.

The pioneer steam and horse railways were found in industrial undertakings; public railways did not come until many years had passed. It is fairly well established that a wooden railway, operated by horses, was in use for industrial purposes in England at the close of the Elizabethan era, when even the stage coach was unknown. Very little is known of this hoary “Rail-Way or Wagon-Way”, as it was called in some old title-deeds. We have more tangible relics of a mining railway which was at work in Germany about the same time, for a wagon and length of track are preserved in a great Berlin museum. The “rails” consisted of straight baulks of timber, and the wagons had wooden flanged wheels. This is remarkable, for the early iron plateways had flanged rails and the wagons plain-tyred wheels. The first railway locomotive in the world, Trevithick's engine of 1804, ran on the industrial tramroad at Penydarran in South Wales. In 1813 we find Hedley's “Puffing Billy” at work on the colliery lines at Wylam, in Northumberland. About a year previously, on June 24, 1812, to be precise, John Blenkinsop’s cog-wheel locomotive made its trial trip, with a load of more than twenty-five tons. George Stephenson’s original inspirations came to him on the Northumbrian colliery lines, and eleven years before the Stockton and Darlington line had been opened as the first steam public railway, he had built his famous “Blucher” for the Killingworth Colliery lines. So far from being a child of the ordinary railway, the industrial railway is its parent.

In the yard of almost any London suburban station an occasional wagon may be seen bearing the name of the Gas Light and Coke Company. All Londoners know the Gas Light and Coke Company. It cooks their food and heats and lights many of their houses. But they do not connect it with railways. Yet the Gas Light and Coke Company is the proprietor of one of the most wonderful industrial railway systems in Great Britain, perhaps in the world. A glance at a map of the London suburban system of the London and North Eastern Railway will reveal a branch line running down from Stratford, on the Great Eastern Section, to Victoria Docks, Silvertown, and North Woolwich. That branch has, in addition, a loop line between the stations of Tidal Basin and Silvertown. From the loop line a solitary branch runs to Beckton.

Beckton is not a suburb, nor a village, nor a town. It is a gas-works. It is not a mere retort house with a few ugly old gasholders, such as may be seen outside a small town, but a gas-works on a colossal scale, to supply the needs of the largest city in the world, after Greater New York. The gas-works covers 360 acres. Beckton is thus a town in itself. Enclosed within those 360 acres are more than seventy miles of railway. The vastness of the place and the completeness of its modern equipment are striking enough, but the extent and modernity of the complex railway system packed into such an area are astounding.

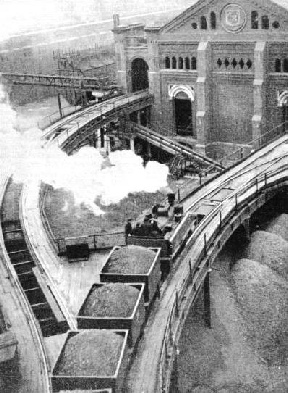

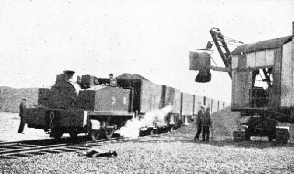

THE “DOUBLE DECKED RAILWAY” at Beckton is often so called because of long viaducts which run above the surface tracks. There are some seven miles of viaduct in the works and altogether over seventy miles of line have been laid within 360 acres. This private system is linked up with the LNER.

The entrance from the main road between East Ham and the Royal Albert Dock affords the most impressive approach. The visitor has considerably farther to walk than if he came into the special terminal station of the LNER, but he gains a far better idea of the vastness of the place. A long avenue, lined with trees, and flanked with workers’ houses, and - provided with a church and an inn, leads through the first part of the company’s property. A railway track runs on either side, that on the right belonging to the LNER, and that on the left to the associated Chemical Products Works, which is really an extension of the Beckton system.

On reaching the inn, which is called the “Friendship”, the visitor is on the threshold of the works themselves, and he begins to realize how that great railway mileage comes to be packed into 360 acres. Running at right angles to the line of vision is a long steel viaduct, while below it, on the ground level, is a complicated triangular railway junction, governed by a large signal cabin. Purely internal railway tracks radiate from the Junction in three directions, while a fourth links it up with the LNER.

The avenue of approach, still lined with trees, continues right into the heart of the works; but now it has three distinct ways, one for a double-track railway, one for road vehicles, and a third for foot passengers. As we pass through the works, we realize how the Beckton lines have come to be called “the double-decked railway”, for on either side it is possible to see long viaducts running above the surface tracks, with sometimes a belt-conveyer running above the high-level lines themselves. Altogether there are upwards of seven miles of railway viaduct in the works. Sturdy little locomotives, painted green, with short wheelbases and low chimneys, puff hither and thither with trains of coal and coke wagons. The place is busier than many of the most important British trunk line junctions.

Altogether, Beckton contains thirty-four locomotives and well over 1,000 wagons of various kinds. A good proportion of the wagons are of the tipping or hopper type, for many of the coke storages are underneath the viaducts, the coke being shot through openings in the decks of the latter. Naturally, there is no passenger service on the Beckton lines, but a saloon coach is used for taking distinguished visitors round the works. This is always hauled by locomotive No. 31, one of two built at Beckton itself. This engine is specially painted and has a brass dome and chimney top. She may well be described as Beckton’s “royal locomotive”, for she has hauled King George V and Queen Mary during a visit which they paid to this wonderful place.

Some of the engines, saddle-tanks known as “Jumbos”, look queer indeed. They were built to a specially low construction gauge to enable them to pass in and out of the retort houses, and the tops of the chimneys come no higher than the tank-tops.

THE “JUMBOS” is the name given to saddle-tank locomotives of this type at the Gas Light and Coke Company's works at Beckton, Essex. They are built to a small loading-gauge to enable them to work into the retort-houses.

Electro-Pneumatic Signalling

All the machinery of the works at Beckton is repaired and renewed in a workshop which would do credit to a full-size railway. So, too, would the tipper beside the coke-handling plant, which will pick up one twenty-tons wagon or two ten-tons wagons bodily, carry them to the top of its tall tower, and tip them over the hoppers, on the same principle as the coaling plants installed at some of the bigger locomotive depots of the British trunk railways. The coke goes down the hopper on to a belt conveyer, by which it reaches the coke-handling plant proper. On the west side of the works an extensive marshalling yard is now being laid out, and this will increase the mileage of this self-contained railway still further. The whole of the Beckton Railway is elaborately signalled. The big signal box at the entrance is to be replaced by a more modern type, with electro-pneumatic signalling. The level-crossing gates at this point are already electrically operated, instead of being laboriously shifted by a great wheel in the cabin.

Down on the river front, where the coal is transferred from the incoming steamers, there is another signal cabin of considerable importance, governing the movements of trains running on and off the piers. It stands high above the viaduct level, affording a wonderful view of the works and the railway system. On the Eastern or “No. 1” Pier, electric colour-light signalling has been installed, similar to that in use on the Brighton electric and many other important main line railways.

There are three complete trains of sixteen wagons each fitted throughout with continuous air-operated discharge doors. For through traffic on to the main line railways there are ninety-three standard ten-tons wagons, similar to those owned by collieries and by the four great British railways. Beckton is not open to the public, though it is one of the greater sights of London. Some idea of it may be gathered, however, from the viewpoint offered by the decks of ships passing along the Thames, and its great piers can easily be seen from the pleasure steamers that ply down the estuary from the Tower Bridge during the summer months.

From this complicated industrial railway let us turn to a short, but none the less notable, line at the other end of Great Britain, namely, the Kinlochleven Railway of the British Aluminium Company, in Argyllshire, Scotland. Kinlochleven is an extraordinary place. Situated among stern mountain peaks at the head of the sea-loch from which it takes its name, and set down in the heart of ancient solitudes, it is yet a busy hive of industrialism, for it is here that the British Aluminium Company has one of its principal works and power stations.

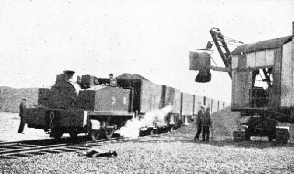

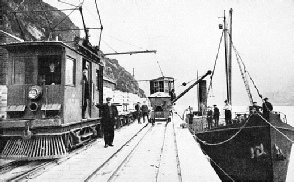

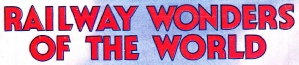

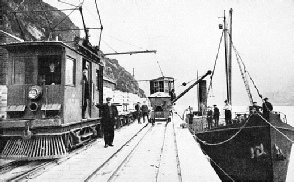

TRANSFERRING ALUMINIUM from an electric train to ship at one of the quays at Kinlochleven. On the left is an electric locomotive, No. 2, and in the background an electric travelling crane. This line, belonging to the British Aluminium Company, was the first electrically operated railway in Scotland.

TRANSFERRING ALUMINIUM from an electric train to ship at one of the quays at Kinlochleven. On the left is an electric locomotive, No. 2, and in the background an electric travelling crane. This line, belonging to the British Aluminium Company, was the first electrically operated railway in Scotland.

Aluminium, it may be recalled, is produced principally from pure alumina oxide, which is treated with a powerful electric current. At Kinlochleven, the power station that generates the current for the production of the metal derives its primary energy from the Blackwater Reservoir, high up on the verge of Rannoch Moor. Naturally, there is plenty of current to spare for general and special purposes in the aluminium-producing town of Kinlochleven. Before the war of 1914-18, Kinlochleven was isolated from any form of land transport whatever; but since 1906 a little electric railway, a mile long, with a double track, has simplified transhipment between the quay and the works. This line was the first electric railway to be operated in Scotland.

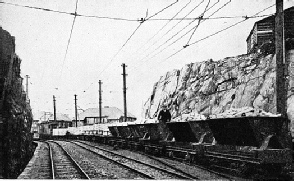

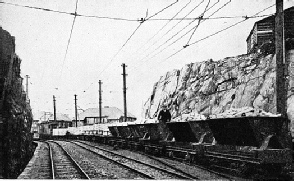

AN INDUSTRIAL LINE IN THE HIGHLANDS. A rock cutting on the British Aluminium Company’s electric railway at Kinlochleven, Argyllshire. The gauge is 3 ft. The power necessary for the production of the metal and for other purposes, including the railway, is derived from Blackwater Reservoir on Rannoch Moor.

AN INDUSTRIAL LINE IN THE HIGHLANDS. A rock cutting on the British Aluminium Company’s electric railway at Kinlochleven, Argyllshire. The gauge is 3 ft. The power necessary for the production of the metal and for other purposes, including the railway, is derived from Blackwater Reservoir on Rannoch Moor.

The gauge is 3 ft, and power is supplied to overhead conductors at 500 to 550 volts DC. The trains, which carry no passenger traffic, are operated by four-wheeled electric locomotives built at Preston, Lancashire, by the firm of Dick Kerr, now incorporated in the English Electric Company, Limited. They are queer little machines, but they are remarkably powerful for their size, and fulfil all the requirements of their design. Until 1920 there was no road to Kinlochleven, and the place remained as isolated from all but maritime approach as it had ever been. In that year a remarkable road built during the war by German prisoners was opened for traffic, but to this day only light materials are brought in by lorry, the electric railway carrying all the heavy goods from ships calling in the harbour. So Scotland’s pioneer electric line remains isolated from the rest of her railway system, for the nearest public railway to Kinlochleven is the LMS line ending at Ballachulish, far down the loch.

A Ship Canal Railway

The British Aluminium Company has a much longer railway in the Scottish Highlands, running between the new works outside Fort William and the dam at the foot of Loch Treig. This is worked by steam; it is used only for maintenance purposes, and has not the really unique features - so far as Great Britain is concerned - of the little Kinlochleven Railway. It is an interesting line, for all that, and carried most of the material necessary in the building of the dam and its attendant works at Fersit and Loch Treig. Those works, incidentally, have included a fifteen-miles long tunnel right through Ben Nevis. This, however, is not a railway tunnel, but is designed to carry the energy-producing water from the loch to the works at Fort William. At the foot of Loch Treig the track of the LNER West Highland line had to be raised to a considerably higher level because of the artificial increase in the level of the loch itself.

The Manchester Ship Canal is not an undertaking which the uninformed are likely to associate with railways. Yet its works include no fewer than 212 miles of railway route, worked by seventy-four locomotives, generally similar to the usual colliery type, and well over 2,000 wagons. This system is not, strictly speaking, an industrial railway, for its operation is all part of the business of transport; but the railways of canal and dock companies have a great deal in common with the purely industrial lines.

At Liverpool, the Mersey Docks and Harbour Board has a network of over 118 miles of railway, and its thirty-six loco-motives include two fireless engines and one driven by internal combustion. Fireless locomotives are referred to later in this chapter. Both the foregoing lines are built to the standard gauge. It was with the Mersey Docks and Harbour Board that the old Liverpool and Manchester locomotive “Lion” performed her last duty as a stationary pumping engine. Built in 1838, she was sold to the Board in May, 1859, and continued to work until quite recent years. She is now preserved, and may be seen by anyone entering Liverpool by the Lime Street terminus of the LMS.

One of the most notable industrial railways in the Midlands is that at the great brewery of Messrs. Bass, Ratcliff and Gretton, Ltd, at Burton-on-Trent, Staffordshire. As at Munich, in Germany, the local water is particularly suitable for the purpose of brewing. The industry has been carried on in the town for well over three centuries, although it is only within the last 150 years or so that it has assumed national - and even world-wide - repute. The railway, which is privately owned, forms an essential part of the brewery equipment of Messrs. Bass, Ratcliff and Gretton, and although the length of the track mileage is only about sixteen, it is a remarkably complete and self-contained undertaking, and the methods of operation resemble those of a main line in miniature.

The word “brewery” is something of a misnomer, since there are three - the Old, Middle, and New Breweries - in addition to the necessary ale stores, cask washing plants, mailings, bottling stores, cooperages, workshops, hop and barley stores, and repair works.

The firm was founded in 1777, and in course of time its premises spread out over the town, until they are to-day situated on either side of the LMS Birmingham-Derby main line. Burton is served also by the LNER via the Nottingham and Derby branch of the former Great Northern Railway, and the Brewery Railway interchanges traffic with both systems by means of exchange sidings at Dixie and Shobnall.

From the traffic standpoint, the Brewery Railway really consists of two sections, the privately owned tracks, and the running roads constructed by the former Midland Railway to provide access to its system. These latter have a total length of approximately ten miles, much of which is carried on the level through the town itself.

Trains of Fifty Wagons

Until the second half of last century the casks of ale were dispatched from the brewery to the railway station in low, two-wheeled carts of special design. The method had obvious inconveniences, and under its Act of 1859, the Midland Company was given powers to build two branch lines that would effect direct communication with its system.

No time was lost, either by the Midland Railway or by the brewery company in setting to work. By 1862 the connecting links had been built, and the Old and Middle Breweries and the cooperage were being served by the firm’s private line. In the following year Parliamentary powers were obtained for the extension of the system so as to reach the New Brewery, which was then under construction, and the building of additional new premises necessitated still further extensions to the Burton lines between 1863 and 1876. As happened to the first public railways, it at once became strikingly apparent that a considerable increase of traffic could be handled with less effort. The greatest load that could be dealt with by a single horse hauling one of the old “floater” carts did not exceed a ton, while the contents of four of these carts could be loaded into two railway wagons, which were, of course, of smaller capacity than the present standard type of vehicle. To-day the Brewery Railway handles trains made up of as many as fifty loaded wagons.

On the inauguration of the railway, traffic continued at first to be handled by horses (which still carry out a small amount of shunting), but animal traction proved inconvenient, both to the firm and to the railway company. A species of traction engine, which could haul eight loaded wagons, was then introduced. At a later date, before the connecting line between the New Brewery and Shobnall - on the other side of the Midland main tracks - had been built, the railway company granted the brewery temporary running powers to enable it to work its own locomotives between Dixie and Shobnall, via the main line and the passenger station. During the period of this arrangement, the firm’s drivers used to be accompanied by Midland pilot-men.

To-day, the whole of the traffic between the LMS sidings at Dixie and Shobnall is normally worked by the firm’s own locomotives, although an occasional trip may be made by a railway-owned engine.

The Bass locomotive stud was inaugurated in 1861, by the acquisition of an engine described as a “square top tank”. This pioneer was built at Burton, by the local firm of Thornewill and Warham. Two years later, a second engine was delivered from the same factory. This was an 0-4-0 saddle tank, a design since adopted as the standard. The present stock consists of eight locomotives, known respectively as “Class A” and “Class B”. The former have 3 ft 6 in coupled wheels, a working pressure of 135 lb per sq in, and weigh, unladen, 23½ tons. The cylinder dimensions are 14 in by 21 in. These engines were built between 1899 and 1913 by the North British Locomotive Company, Ltd, Glasgow. The “Class B” locomotives are much older. One, also constructed by Thornewill and Warham, was built in 1869; while the second, one of the two originally known as the “Triangle” class, was built in 1890. Since then it has been twice rebuilt - in 1909 and 1924. The leading dimensions of the “Class B” engines are: coupled wheel diameter 4ft, working pressure 120 lb, unladen weight 22¼ tons, cylinders 14 in by 20 in.

Both types are capable of hauling from forty to fifty loaded wagons, a considerable total for such small engines, in view of the gradients on parts of the system. The standard livery is most attractive, the engines being painted a bright red, with brass domes and copper-capped chimneys. Characteristic features of their design are the relatively long overhang at either end, and the unusually large diameter of the buffer faces, the object of this being to prevent “locking” on curves. The working stock also includes a four-wheeled visitors’ saloon and a number of private wagons.

For a private line of this description, the traffic on the Brewery Railway is exceptionally heavy. On a normal working day, the firm’s locomotives handle an average of a thousand wagons, but this figure is often exceeded. Rather less than half (the number usually ranges between 350 and 400) is represented by inward empties, and about the same number is daily loaded for dispatch, the balance being made up of inter-brewery traffic. A few words of explanation are necessary about inter-brewery traffic. While each of the breweries is worked as a self-contained unit, the operation of the business as a whole necessitates a considerable amount of internal traffic, such as the distribution of coal, barley, and malt. Since, as already mentioned, the various breweries and other buildings are scattered over a wide area, this traffic assumes definite importance in the aggregate.

Brewery “Specials”

So far as possible, train movements are worked to a definite time-table, and operation is based on the firm’s book of “Rules and Regulations”, which is recognized by the LMS Company. On certain sections of the private lines an additional code is in use. The firm maintains its own Railway Department, comprising clerical, operating, permanent way, and engineering staffs; and locomotive repairs and renewals are undertaken at its own “shops”. The railway is under the control of a Traffic Manager, and there is an elaborate system of traffic control, to which more detailed reference is made below.

There is, of course, a material difference between the nature of the inward, or arrival, and that of the outward traffic. The former, which handles the fuel and raw materials necessary for brewing, is divided into seven categories. These are the “up brewery” trains conveying malt, the barley trains for the malting department, empties to the ale-loading stations, empty casks for the cooperage department, hop department trains, coal trains, and “oddments”, the last being mainly devoted to the requirements of the engineering and general stores departments. There are five loading stations, and the arrival of the empties is timed to correspond with the departure of the outward bound loaded trains. Another characteristic of the working is that the “brewery trains” have the right of way over all other inward traffic, so as to ensure the utmost punctuality in delivery.

This inward traffic is distinct from the internal traffic, which deals with the conveyance of maltings from the stores to the breweries, the carriage of barley to the maltings, and the carriage of casks from the cleaning plants to the breweries. Inward traffic is operated by “trip trains” working to a fixed timetable and stopping only to deliver at any of the three breweries. Provision is made for four of these trains, which leave Shobnall between 9 am and 2 pm, and have a uniform allowance of thirty-five minutes for the whole journey, including stops at the three breweries. The trains carrying the clean casks run to each brewery three times or more daily, according to requirements.

The normal schedule embraces twenty-seven trains a day, between 7.40 am and 3.05 pm. This comprises traffic under the following categories: clean casks from the Middle Yard cooperage to the Middle Brewery and from the Shobnall cooperage to the Middle and New Breweries respectively; ale from the New Brewery to the ale-loading station at Shobnall; similar traffic from the Old Brewery to the Dixie loading station; and malt trips from Shobnall to the Middle and New Breweries. Strict punctuality in running is insisted on, since if this were not maintained time would be lost by the workers in the various departments waiting to carry out their appointed tasks.

The “Bass Specials” serve various parts of the country, and are made up to as many as forty or fifty wagons. These are booked to leave at fixed times, but do not necessarily run daily. For instance, the “Scotch Special” is scheduled to run three times a week. The working of this train is of particular interest. It runs through from Burton to Leeds, where the engine is changed, and then travels non-stop to Carlisle, where connexions are in waiting to take the wagons on to their various destinations.

The various types of services in daily operation for inter-departmental traffic and for that worked in co-operation with the LMS and LNER number eleven. Working is complicated by the fact that, while the arrival and departure sidings are situated at opposite ends of the firm’s premises, much single-line operation is necessary. To deal with the problem of handling traffic in either direction over a single road, the Control Department was created.

This consists of a head control office and sub-offices at Shobnall and Dixie, which are in telephonic communication with the head office. The latter is responsible for train movements over the whole system, and is in communication with every department served by it. The sub-offices handle the details of operation at their respective exchange sidings. The head office also maintains constant touch with the LMS and LNER. The trains handed over to the two railway companies are made up with the wagons in correct junction order.

Another of the duties of the control office is to deal with problems arising out of a wagon shortage or surplus. Every morning a classified return is made out of every wagon standing on the exchange sidings or within the brewery premises, and it is claimed that demurrage has virtually been eliminated.

Signalling control is exercised both by private cabins and by those of the LMS, the latter on those sections where Bass trains have running powers. Telephonic communication is provided between the firm's signal boxes. Signals are installed both within the brewery limits and at public level crossings. The time allowed for train and engine movements at a crossing is one minute, and should there be a delay in excess of two minutes the signalman records the fact, and the matter is investigated by the control office. Such delays are rare, and are normally due to weather conditions, such as fog or frost causing an engine to slip. The possibility of undue detention is lessened by limiting the number of wagons allowed to cross a public thoroughfare on any one journey.

Punctual and efficient working is ensured by an elaborate organization that is comparable, even if only on a small scale, with that of a main-line railway. This involves the compilation of a number of forms and returns, some of which are of a specialized nature. These include empty wagon requisitions, loading slips to foremen ale loaders, daily statements of forwarding at each of the breweries, daily returns of wagons standing under load, and “Due Away Loaded” cards. The loading slips give particulars of each consignment, together with its destination, loading times, particulars of the place where the consignment is to be found in the store-rooms, and various other details. Instructions to loaders are drawn up in advance by the invoicing and forwarding department and distributed by the traffic department, which keeps in constant touch not only with all the brewery departments but also with the LMS and LNER.

Another great brewery railway is the system owned by Messrs. Guinness at Dublin, which includes both narrow-gauge and main exchange lines.

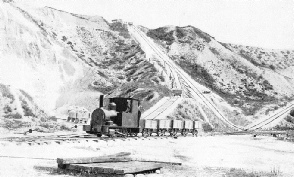

Great quarries form the situations of many very remarkable railways, and one of the most noteworthy in the British Isles is the system in operation at the great Dinorwic slate quarries near Llanberis, in North Wales. This is really not so much a system as a series of systems, for a huge mountain-side of solid slate has been cut into terraces, one above the other, and each terrace has its own particular railway line. Slate has been quarried at Dinorwic for centuries, and rail transport has been in use there for more than a hundred years.

A PASSENGER TRAIN on the Dinorwic Slate Quarry Railway, North Wales. On the quarry terrace a light 1 ft 11½ in gauge line serves the working face, but a 4 ft gauge line, seven miles long, leads to Port Dinorwic. A six-coupled tank used on this section weighs twenty-five tons.

On each of the terraces of the quarry a little 1 ft 11½ in gauge serves the working face, the track being portable to facilitate rapid alteration to the layout as the workings change.

Welsh Quarry Lines

Small tank engines provide the motive power. These weigh about six tons apiece, and can be moved from terrace to terrace by means of inclined planes, which are also regularly used for the transfer, by cable, of the slate trucks between terrace and ground level. From the transfer planes, a 4-ft gauge line leads away across country to the transhipment point at Port Dinorwic on the coast. At Port Dinorwic another inclined plane leads down to the quays on a gradient of 1 in 4. The method of conveying the slates from the working faces to the coast is peculiar. Loaded up on to the 1 ft 11½ in gauge trucks, the fragile freight is transferred by means of the first plane to the 4-ft gauge line. Here, instead of the slates being unloaded and loaded again, a proceeding which would greatly increase the risk of breakages, the small trucks are loaded bodily on to the 4-ft gauge wagons. A six-coupled side tank engine, weighing about twenty-five tons, is then attached and the load moves off along the seven-miles-long “main line” to Port Dinorwic, where the inclined plane transfer process is repeated, thus eliminating transhipment during the overland part of the journey. This line, known as the Padarn Railway, is not open to the public, but passenger trains are run over it purely for the benefit of the many hundreds of men engaged on work in the quarries.

Another remarkable Welsh quarry railway is that on the Penmaenmawr Mountain, Caernarvonshire. Here again the inclined plane system is well exemplified. Visitors to Cornwall, too, will find a noteworthy example of the plane and terrace system at work in the vast slate quarries at Delabole, close to the most westerly section of the Southern Railway, from which they are clearly visible. The Delabole quarries have been worked since Elizabethan days, and probably earlier.

But the Londoner, with little opportunity for travel to Wales or Cornwall, may see a lesser, but very complete and interesting quarry railway system within about forty-five minutes of the metropolis. This operates in the great chalk pits and limeworks of the Dorking Greystone Company, adjacent to Betchworth Station, on the Southern Railway line between Dorking and Reigate Anyone who knows this part of Surrey will have noticed two gashes in the green face of the North Downs, only a mile or two eastwards from Box Hill.

A QUARRY RAILWAY SYSTEM in Surrey which operates in the chalk pits and limeworks of the Dorking Greystone Company. A standard gauge line connects the kilns with the Southern Railway’s siding at Betchworth, while the narrow-gauge railway shown runs up to the working face.

The quarries and their railway are additionally easy to observe at close quarters, because an ancient right of way runs right across the workings, passing over the railway on a brick bridge midway between the lime kilns and the quarry itself. A standard-gauge railway connects the kilns with the Southern Railway’s siding at Betchworth, while a narrow-gauge railway runs up from the kilns to the working face. There are extensive sidings in the immense white pit of the quarry, while terrace working goes on at a considerable elevation above them.

For the transfer of wagons to and from the high level an interesting process takes place. There is a steeply inclined plane connecting the two levels, while more or less parallel to it there is a gentler incline. A line of rollers runs between the summits of the two planes, over which a wire rope is passed. When wagons are to be hauled up, that section of the wire rope which comes down the steep incline is coupled up to them. A locomotive, which normally remains on the lower level, then puffs up the easier incline, and is coupled to the other end of the wire rope. The locomotive now begins to haul and, with the gradient in her favour, moves steadily forward, causing the wagons to run, in the reverse direction, rapidly up the steep plane. To bring down loaded wagons, the process is reversed. The locomotive hauls in the first instance, and acts as a powerful brake on the descending loaded wagons in the second.

The engines at Betchworth, though of rather old design, are admirably suited to their particular kind of work. One of them is something of a curiosity; she has a vertical boiler, which has earned her the name of the “Coffeepot”. This name is now in official use. The cylinders are also vertical, and are connected to the driving axle by gear wheels The “Coffeepot” was built in 1872, and at the present time is the spare engine on the standard gauge line. The other engines are ordinary 0-4-0 side tanks

Fireless Locomotives

As might be expected in Great Britain, the colliery companies and ironworks to-day own the lion’s share of the industrial railways: and anyone travelling through the coalfields of England, Scotland, and Wales will see their connecting lines coming in to join the main trunk railways at surprisingly frequent intervals. Their wagons may be seen in goods yards all over the country, however remote from their places of origin.

The ordinary colliery locomotive is of a straightforward tank engine design, able to negotiate sharp curves, and exceptionally powerful for its size. But sometimes, as we shall see below, an unusual type of locomotive makes its first appearance on an industrial railway.

The “Garratt” type of locomotive is exemplified in Great Britain by one engine on the LNER and by thirty-three on the LMS, all built in recent years. But about 1923 Messrs. Vivian & Sons, a South Wales firm, ordered from Beyer, Peacock & Co the first “Garratt” locomotive ever put into service in the British Isles. The engine was an immediate success; it has the 0-4-0 + 0-4-0 wheel arrangement, and has been found to do the work of two ordinary tank locomotives at a greatly decreased cost. Others have appeared on industrial lines in South Wales since the advent of this engine.

Another unorthodox type of engine, the use of which has been practically confined to industrial railways, is the fireless steam locomotive. In chemical works, petrol refineries, and other places where flying sparks would be very dangerous, this type is of inestimable value. In appearance, it recalls an ordinary locomotive without a chimney. The boiler is replaced by a steam container, surmounted by a dome and safety valve, which supplies steam to the cylinders continuously for several hours. The steam container is filled with water at a high temperature to about three-quarters of its entire capacity; the remaining space in it is charged with superheated steam from a central stationary boiler. The machine is so arranged that the steam, on entering the container, is mixed with the hot water, the effect of which is to increase the pressure, a certain loss of which occurs in the process of charging. This type of locomotive has the great advantage common to all steam engines, namely, simplicity. The first fireless steam locomotive was produced by the Borsig Locomotive Works of Berlin in the early years of the present century, and since then many engines of this type have been built.

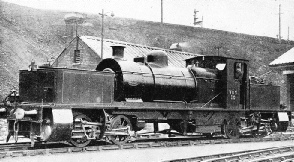

THE FIRST “GARRATT” LOCOMOTIVE put into service in Great Britain. The engine - seen here on an industrial line at Swansea - has the 0-4-0 + 0-4-0 wheel arrangement, and can do the work of two ordinary shunting locomotives at less cost.

You can read more on

“Diesel Shunting Locomotives”

and

“The Festiniog Railway”

and

“Industrial Railways 2”

on this website.

You can read more on the

Beckton Gas Works

in Wonders of World Engineering

TRANSFERRING ALUMINIUM from an electric train to ship at one of the quays at Kinlochleven. On the left is an electric locomotive, No. 2, and in the background an electric travelling crane. This line, belonging to the British Aluminium Company, was the first electrically operated railway in Scotland.

TRANSFERRING ALUMINIUM from an electric train to ship at one of the quays at Kinlochleven. On the left is an electric locomotive, No. 2, and in the background an electric travelling crane. This line, belonging to the British Aluminium Company, was the first electrically operated railway in Scotland. AN INDUSTRIAL LINE IN THE HIGHLANDS. A rock cutting on the British Aluminium Company’s electric railway at Kinlochleven, Argyllshire. The gauge is 3 ft. The power necessary for the production of the metal and for other purposes, including the railway, is derived from Blackwater Reservoir on Rannoch Moor.

AN INDUSTRIAL LINE IN THE HIGHLANDS. A rock cutting on the British Aluminium Company’s electric railway at Kinlochleven, Argyllshire. The gauge is 3 ft. The power necessary for the production of the metal and for other purposes, including the railway, is derived from Blackwater Reservoir on Rannoch Moor.